A roller door in a shipping container gives you secure, weatherproof access to your container without removing the original doors. These metal shutters roll up and down over an opening cut into the container wall, creating a convenient entry point for storage, workshops, or retail spaces. You can install them on the side or end of standard 20ft or 40ft containers.

This guide covers everything you need to know about adding a roller door to your shipping container. You'll learn why these doors make sense for Australian conditions, how to choose the right size and style, what it costs to buy and install them, and whether a DIY installation suits your project. We'll also share practical tips from container modification experts to help you avoid common mistakes. By the end, you'll know exactly how to plan your container roller door project and where to source quality doors for your specific needs.

Why put a roller door in a shipping container

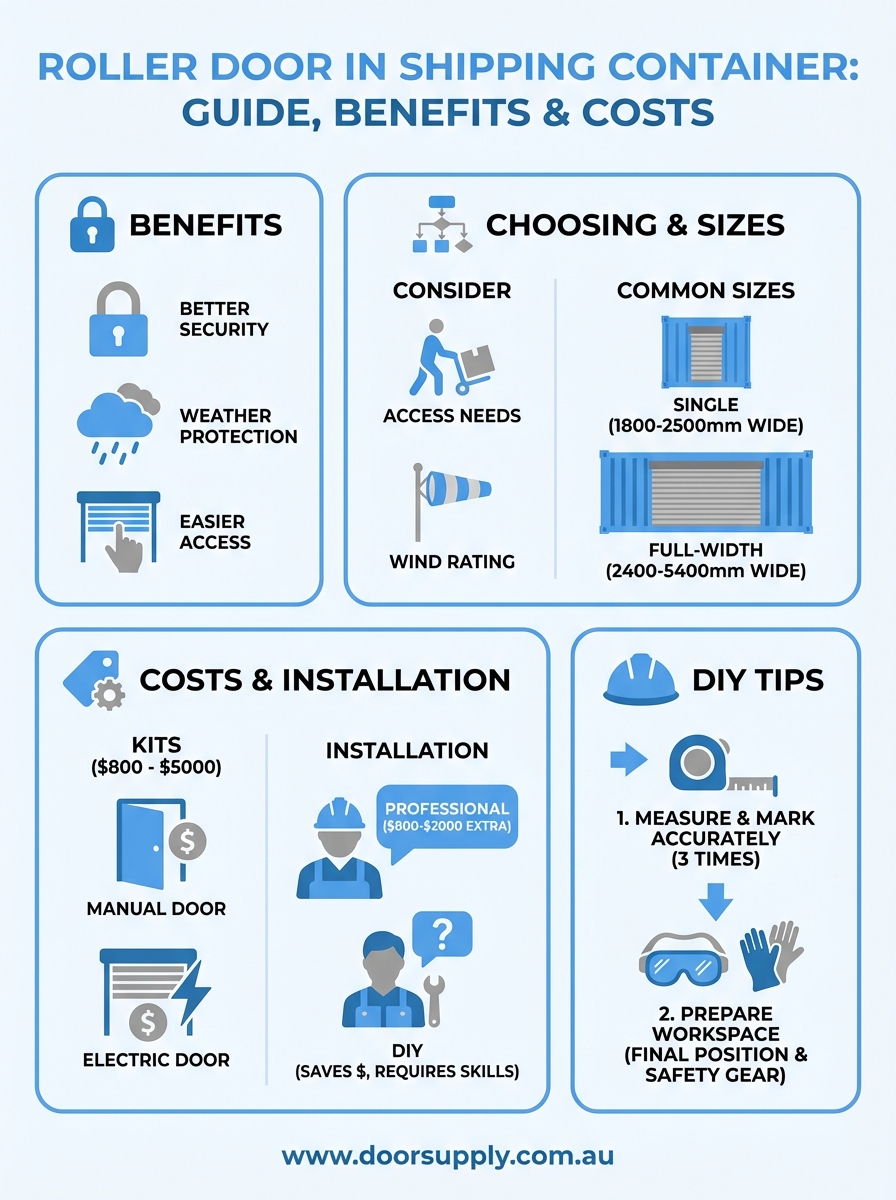

Installing a roller door in a shipping container transforms how you use the space. Standard shipping container doors swing outward on hinges, which requires clearance space and takes time to open and close. A roller door solves both problems by rolling straight up into a compact housing above the opening. You also protect vulnerable entry points from Australia's harsh weather, including driving rain, dust storms, and strong coastal winds that can damage standard container doors over time.

Better security and weather protection

A roller door in shipping container applications gives you lockable security that's harder to force open than traditional swing doors. The metal slats interlock as they roll down, creating a solid barrier against break-ins and vandalism. You'll also keep moisture, dust, and pests out more effectively, which matters if you're storing tools, equipment, or inventory that needs protection from the elements.

Roller doors seal better than standard container doors, reducing moisture damage and keeping your stored items dry year-round.

Easier daily access

You can open a roller door with one hand in seconds, compared to wrestling with heavy container doors that require significant physical effort. This convenience matters when you're accessing your container multiple times daily for work or business purposes.

How to choose the right container roller door

Selecting the right roller door in shipping container projects depends on how you'll use the space and where you'll place the container. You need to match the door specifications to your daily access requirements, local weather conditions, and budget constraints. Making the wrong choice means you'll face ongoing frustration with doors that don't suit your workflow or fail prematurely under harsh Australian conditions.

Consider your access needs

Think about how often you'll open the door and what you'll move through it. If you're running a workshop and moving large equipment daily, you need a wider door with a robust motor that handles frequent cycles. Storage containers accessed weekly can work with manual operation and narrower openings. You should also measure your tallest items to ensure they'll fit through the opening without tilting or disassembly.

Material and wind rating

Choose galvanised steel or aluminium doors rated for your location's wind conditions. Coastal areas and exposed sites need wind-locked doors that withstand cyclonic conditions above 55 metres per second. Standard domestic roller doors suit suburban locations with moderate weather. You'll pay more for wind-rated doors, but replacing a damaged door costs significantly more than the initial upgrade.

Wind-rated roller doors prevent structural damage and costly repairs in high-wind regions, making them essential for coastal and rural container placements.

Check that the door colour matches or complements your container's Colorbond finish for a professional appearance that holds its value.

Common roller door sizes for shipping containers

Standard roller door sizes match typical shipping container dimensions, but you'll need to cut an opening that fits your chosen door model. Most suppliers offer roller doors between 2100mm and 2400mm high, with widths ranging from 1800mm to 5400mm depending on whether you want a single access point or full-width opening. The door housing adds approximately 400mm+ above the opening, so you need to account for this clearance when planning your installation.

Single access doors

You can install compact roller doors measuring 1800mm to 2500mm wide for personal access and moving standard equipment. These doors suit workshop containers, storage units, and retail spaces where you don't need to drive vehicles inside. A 2100mm high by 2100mm wide door provides comfortable access for most applications while maintaining structural integrity in the container walls. The smaller opening also costs less to cut and finish properly. It is possible to exact cut the container wall so no additional framing is required, you will need to order an exact size roller door and cut the opening so you have the flat faces to fix directly to.

Full-width container openings

Full-width roller door in shipping container installations require doors spanning 2400mm to 5400mm to cover an entire container end. These dimensions suit 20ft containers (approximately 2400mm wide) and 40ft containers (roughly 2400mm per standard door bay, with dual doors totaling near 4800mm). You'll need professional structural reinforcement around these large openings to prevent the container from warping under its own weight.

Full-width openings require steel reinforcement beams above and beside the door frame to maintain container structural integrity and prevent sagging over time.

Costs, kits and installation options

Roller door in shipping container installations cost between $900 and $4,500 depending on door size, material quality, and whether you hire professionals or install yourself. Basic kits include the door, tracks, brackets, and locking mechanism, while premium packages add electric motors and remote controls. You'll also need to budget for cutting the container opening, which requires angle grinders, cutting discs, and safety equipment if you're doing it yourself.

Roller door kit prices

Standard manual roller door kits for 2100mm x 2100mm openings start around $800 to $1,200 from Australian suppliers. You'll pay $1,500 to $2,500 for the same size with an electric motor included. Full-width doors for 20ft containers cost between $2,000 and $3,500, while 40ft container doors reach $3,500 to $5,000 for quality wind-rated units. These prices reflect Australian-made Colorbond or Zincalume steel doors, which last longer in harsh conditions than imported alternatives.

Professional installation vs DIY

Professional installation adds $800 to $2,000 to your project cost but guarantees structural integrity and weatherproofing. Installers reinforce the opening with steel frames welded into place, apply proper seals, and ensure the door operates smoothly. They also handle council permits if your location requires them. DIY installation saves money but demands welding skills, metal-cutting experience, and proper safety equipment including respirators for cutting galvanised steel.

Professional installation prevents costly mistakes like inadequate reinforcement that causes container warping, making it worthwhile for valuable container conversions or commercial applications.

Most suppliers ship door kits Australia-wide within 12 to 20 business days, with freight costs factored into the quote based on your location.

Tips for planning a DIY container door project

Planning your roller door in shipping container installation prevents expensive mistakes and ensures the door operates properly for years. You need accurate measurements, proper tools, and safety equipment before cutting into your container. Most DIY failures happen because people underestimate the structural changes required or skip critical reinforcement steps. Taking time to plan each stage saves you from having to repair damage or hire professionals to fix poor workmanship.

Measure and mark accurately

Measure your door frame dimensions three times before cutting and mark the opening with chalk or marking paint. You should confirm that your measurements account for the door housing, side tracks, and clearance space needed above and beside the opening. Check that the container sits level before marking, as an uneven base throws off your measurements and causes installation problems. Use a spirit level to draw perfectly vertical and horizontal lines, which keeps your door aligned and operating smoothly.

Prepare your workspace

Set up your container in its final position before cutting, as moving it afterwards with a large opening weakens the structure. You'll need angle grinders, cutting discs, welding equipment, and full safety gear including respirators, gloves, and eye protection. Galvanised steel releases toxic fumes when cut or welded, so work outdoors with good ventilation.

Always wear proper respiratory protection when cutting or welding galvanised steel containers to prevent metal fume fever and long-term health damage.

Next steps

You now understand how a roller door in shipping container installations improves access, security, and weatherproofing for Australian conditions. Start your project by measuring your container opening precisely and deciding whether you need a compact access door or full-width opening. Research wind ratings for your location to ensure your door withstands local weather conditions without damage. Get quotes from multiple suppliers that include shipping to your area, and compare manual versus electric operation based on how frequently you'll access the space.

If you're ready to order a quality roller door for your container project, browse custom-made roller doors at DoorSupply for Australian-made options with free nationwide delivery. You'll find doors manufactured in Melbourne using Bluescope Colorbond steel, with exact measurements to suit your container dimensions. Contact their team for technical advice on sizing and installation requirements specific to your project.